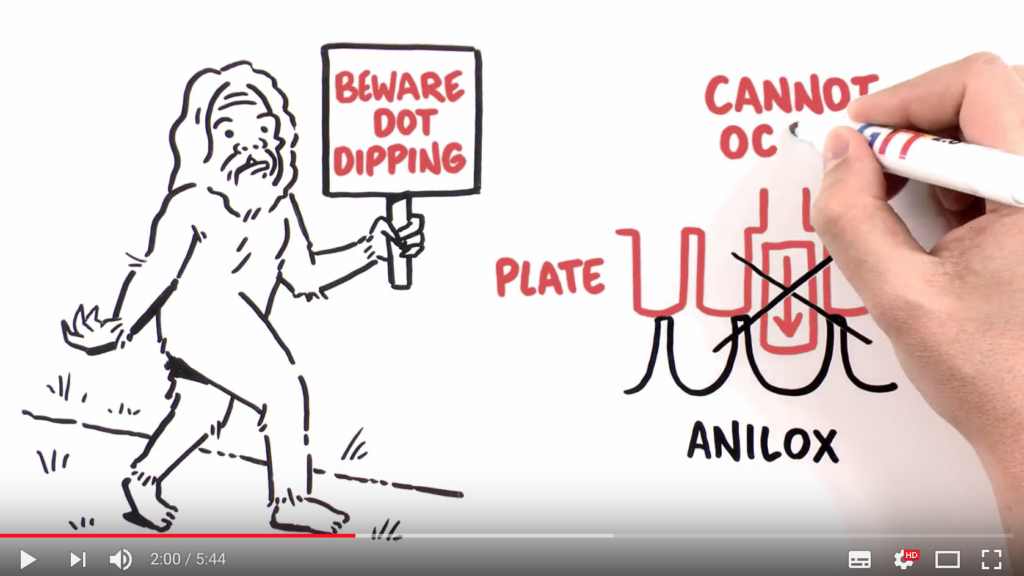

Do you solve problems or make them not happen?

It is often thought that the skill of a printing press operator is linked to his ability to solve problems. It’s actually more important to make sure these problems don’t happen. And this is achieved with an in-depth knowledge of the variables and components that interact in the printing process.I covered this in the article […]

Do you solve problems or make them not happen? Read More »