Can you recognise the cause of dirty printing in highlights?

It is important to understand wether the issue is related to dot dipping, thus plate-to-anilox ratio, wrong metering of the anilox surface or other causes.

What is visible on the printed product is a generally a dirty aspect that forces to repeated stops for plate cleaning and press downtime.

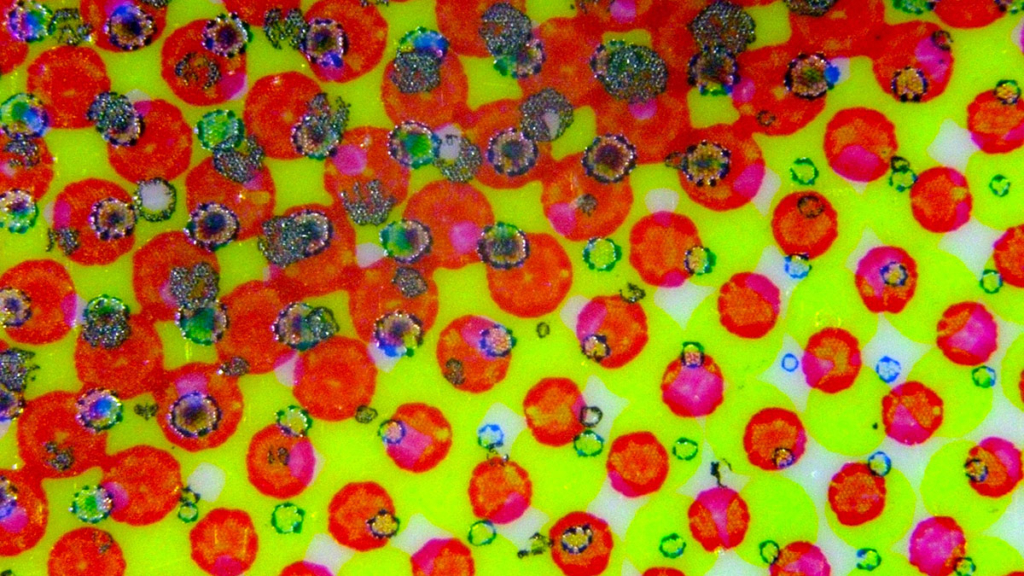

Take a look with a lupe or a microscope: if you see some printed dots with a somewhat random dot-gain around the edge of the dots, this is what is normally described as “dot dipping“: too-small dots on plate dip in too-wide anilox cells openings.

If you see droplets of ink out of the grid of the dots, this is what is normally described as “ink spitting“: ink flooding due to wrong metering of the doctor blade on the surface of the anilox and lifted by the surface tension of the back of the blade.

In case of dot-dipping, increase the size of highlight dots on plate by using a lower linescreen or a hybrid screen, or increase the line count and reduce the volume of the anilox roll.

In case of ink spitting, ensure that the metering blade is effectively working at 30° contact angle and with a contact area that is possibly smaller than 150µ (this requires microscopic analysis of the edge of a worn doctor blade).

Do you happen to have both defects? Well, it’s time to go through a proper calibration of your system, starting from optimisation.