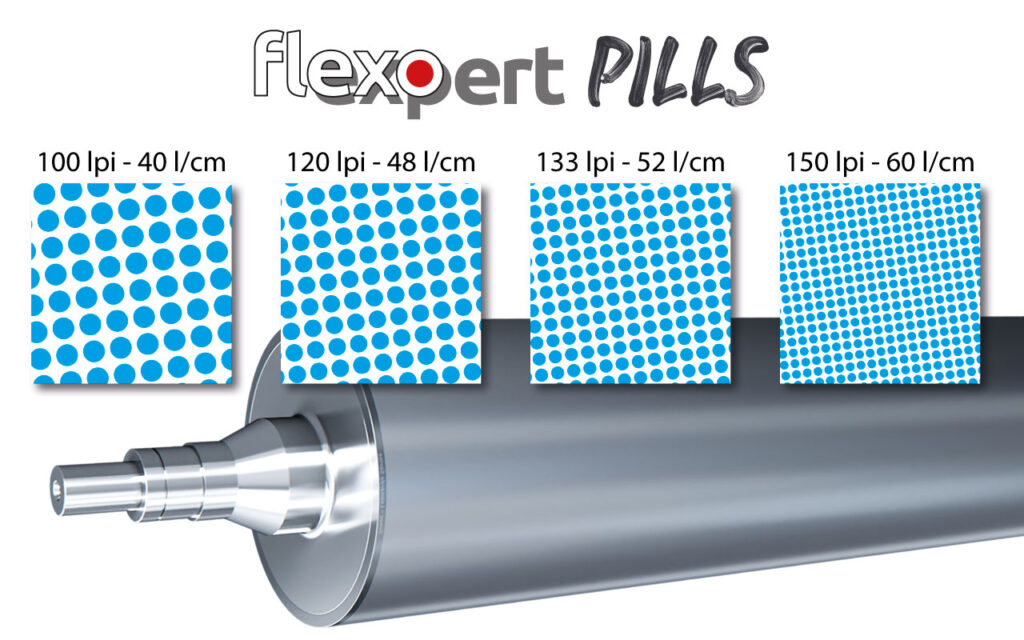

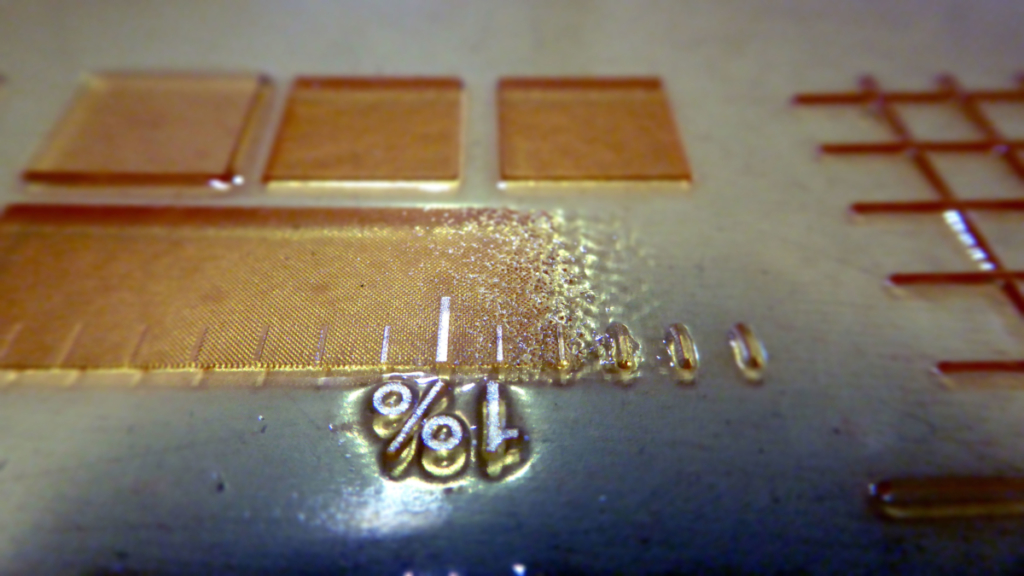

No… There is no ratio between plate and anilox screencounts.

We often hear about a numerical ratio between the screencounts of the flexo plate and that of the anilox roll.In ancient times it was also said that it had to be an odd ratio, like 1:3, to avoid moirée.Then numbers like 1:5, 1:6, 1:7 arrived…There actually is a relationship but it’s not really based on […]

No… There is no ratio between plate and anilox screencounts. Read More »